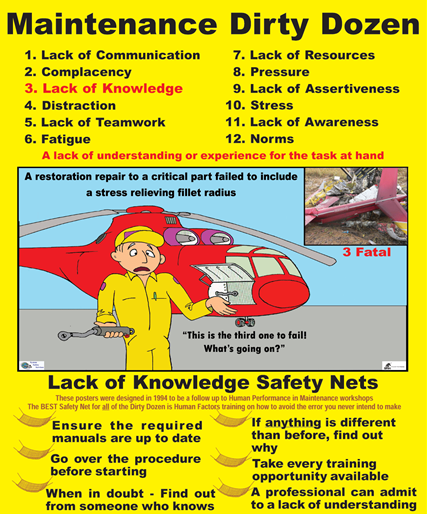

#3 of the Dirty Dozen Is “Lack of Knowledge”

So, just what is a Lack of Knowledge?

Any competent human factors instructor will tell you that "Lack of knowledge" is when you lack the knowledge to complete a task correctly. Many new employees have what we call a “Lack of Knowledge” or lack of experience.

Let’s face it, in these times of ever-changing technology, we are sometimes faced with a task without having all of the required information to correctly complete the task.

To counteract this, the aircraft companies attempt to provide the correct amount of detail in their manuals or work cards (without boring you into complacency).

The key to “Lack of Knowledge” is to understand each step of what you are doing. Technical reps get paid very good money to answer any questions you may have.

I just want to share this quick story with you:

A Navion had recently been inspected and was on a final flight before it was to be sold.

Only a few minutes from the airport, a few specks of oil appeared on the windshield, followed shortly after by a lot more. The pilot was unable to see through the thick film of oil now covering his windshield and side windows but somehow managed to pry the canopy open enough to see out a 2-inch gap. As he touched down with no forward vision, the aircraft drifted to the left until the wing tip struck a bush on the side of the runway and caused the aircraft to tow 180° before coming to a stop.

The aircraft was severely damaged, but fortunately, the occupants were not injured.

Why did this happen?

The Hartzell propeller on the Navion uses a rubber diaphragm attached to the front of the engine to change the propeller blade pitch. Regulated engine oil pressure is used to move the diaphragm.

As you might have guessed, the diaphragm had a one-inch split in it from which the oil flowed. The propeller manufacturer’s manual calls for the diaphragm to be replaced at propeller overhaul every 250 hours or every two years. The logbooks revealed that the propeller had been overhauled 3 times and the engine once in the previous 12 years. But there was no record of a diaphragm change.

What are some of the Safety nets when you “Lack the knowledge”?

- Ensure the required manuals are all up to date

- Go over the procedure before starting

- If you have a doubt, ask someone who does know

- If anything is different from before, find out why

- Take every training opportunity given to you

- Remember a professional can admit to a lack of understanding

Remember: Training = Knowledge = Safety

Pro-tip: When your safety team proactively identifies hazards for the hazard register, ensure that they consider the human factors' elements.

Related Aviation Human Factors Articles

- Let’s Talk Human Factors - Origin of Dirty Dozen

- Let’s Talk Human Factors - Lack of Communication

- Let’s Talk Human Factors: Distraction Is #4 of the Dirty Dozen

Last updated January 2026.