What Is Continuous Improvement in Aviation SMS

Continuous improvement in aviation SMS programs in the formal process by which safety programs correct substandard safety performances that have been identified. Correcting substandard performance has several basic elements:

- Identify causes of substandard performance;

- Identify efficient solutions for those causes; and

- Implement those solutions.

Solutions and implementation of those solutions happen through corrective-preventative actions. Corrective-preventative actions are exactly as they sound - actions are taken to bring safety concerns into an acceptable level of safety (ALoS) by:

- Preventing hazard/risk occurrences causes;

- Detecting hazard/risk occurrence causes; or

- Correcting hazard/risk occurrence causes.

Continuous improvement is the final step of the Safety Assurance process.

What Prompts the Continuous Improvement Process

The continuous improvement can be either proactive or reactive risk management. During the safety assurance process, safety concerns are identified, such as through:

- Audits, inspections, or other evaluations (proactive);

- Data analysis activities (proactive); or

- Reported safety concerns (reactive).

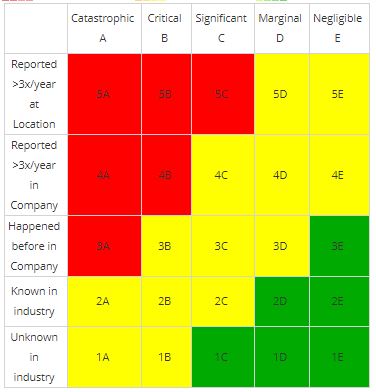

After a safety concern is identified, it will be analyzed and then assessed, such as with a risk matrix. If the risk assessment of the safety concern is higher than the organization’s defined acceptable level of safety, then the continuous improvement process will be initiated.

The Process of Continuous Improvement

The process of continuous improvement is fairly straightforward. Once the substandard performance has been identified, safety managers will:

- Identify root causes of the safety concern;

- Brainstorm solutions – safety risk controls – to correct the root causes;

- Assess the safety concern as if the solution has been implemented, and ensure that the solution brings the concern within the acceptable level of safety; and

- Implement the solutions through the use of corrective-preventative actions.

It’s important to verify that proposed solutions will actually correct the problem, or else waste time and resources implementing ineffective risk controls.

What Continuous Improvement Looks Like in Real SMS

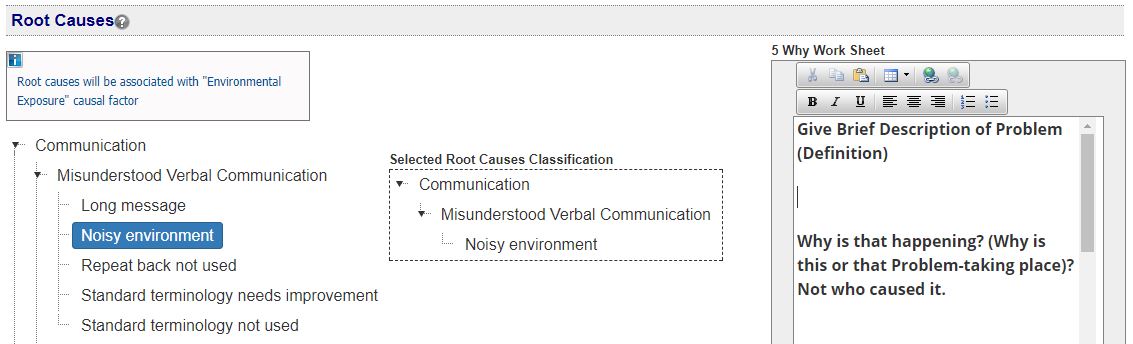

Here is an example continuous improvement process that is used in real aviation SMS programs. First, safety managers will:

- Do a risk assessment;

- Perform root cause analysis; and

- Identify the root causes of the safety concern.

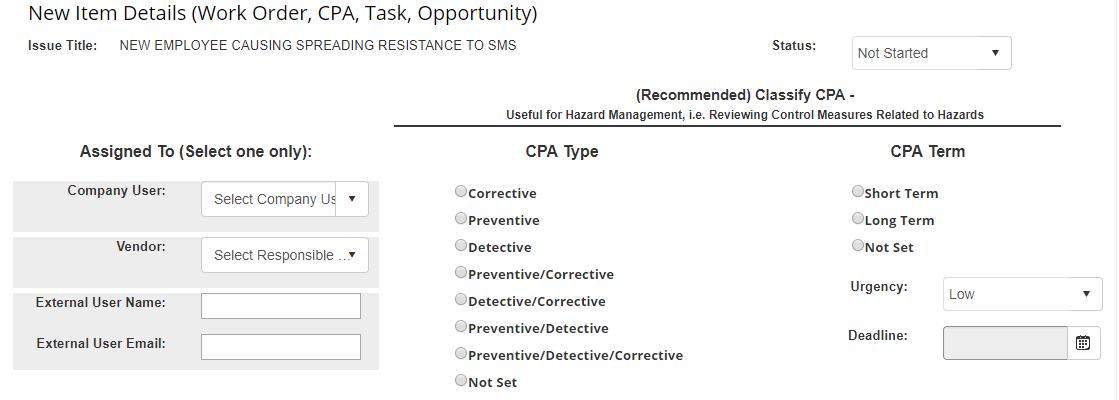

Based on the identified root cause analysis and root causes identified (classified), subject-matter experts will create corrective actions and assign them to employees.

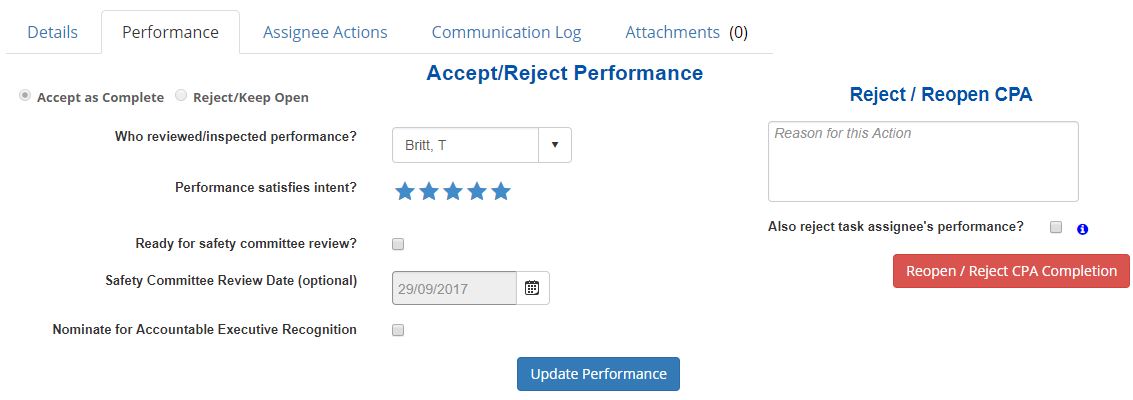

The employees will complete the corrective actions, and then managers will accept or reject the performance and give the CPA a rating for future reference.

Best Tools to Satisfy Continuous Improvement Compliance

Having the proper tools will significantly aid in your ability to practice high-quality continuous improvement of your SMS program. Some of these tools are:

- Corrective action manager;

- Internal evaluation tool;

- Safety performance monitoring tools (charts, tables, metrics); and

- Auditing tool.

Indications of Continuous Improvement Compliance

Indications of SMS compliance for continuous improvement are:

- You have documented your continuous improvement process;

- You have evidence of creating CPAs are assigned to relevant employees; and

- You have documented evidence for reviewing the effectiveness of the control measures.

Related Aviation SMS Continuous Improvement Articles

- How to Be Compliant With Continuous Improvement of SMS

- How to Demonstrate Continuous Improvement in Aviation SMS

- FAA Part 5 Compliance | Safety Assurance Continuous Improvement

To see how you can automatically be compliant with the continuous improvement process, see these demonstration videos:

Last updated December 2025.