What Is an SMS Operational Risk Profile (ORP)

Under the umbrella of many SMS compliance agencies, an operational risk profile (ORP) is a requirement that is the core of your hazard, risk, and control measure accountability. That’s another way of saying that all risk mitigation “resources” are identified in your ORP.

But what are risk mitigation “resources?” These are any elements that are relevant to risk exposure and risk reduction. Resources can be:

- Knowledge;

- Budgets;

- Physical resources;

- Human resources;

- And so on.

Most commonly, SMS programs that use ORPs will divide their resources into categories based on either the SHELL model or 5M model.

SHELL and 5M Model to Organize Safety Resources

The SHELL model breaks down resources into the following four categories:

- Software: non-physical aspects of a safety program that govern how it operates, such as:

- Safety policy/procedures

- Rules

- Incentives

- Regulation

- SMS software

- Hardware: physical elements of SMS, such as:

- Aircraft

- Equipment

- Tools

- Buildings

- Computers

- Environment: the actual environment in which the SMS exists that may impact the SMS, such as:

- Physical location

- SMS parent organization

- Economy

- Politics

- Liveware: the human element in an SMS program, like:

- Safety culture

- Education level

- Experience

The 5M model is similar to the SHELL model, but uses five categories that are organized slightly differently:

- Man: human element in an SMS program (see SHELL model Liveware);

- Management:supervisory capacity of management in terms of:

- Regulations

- Policies

- Attitudes towards safety

- Safety training

- Machine: physical elements of SMS program (see SHELL model Hardware);

- Medium: the environment in which the SMS functions (see SHELL model Environment);

- Mission: the type of task(s) an organization uses to fulfill goals, such as:

- Safety transportation of passengers

- Quick loading/unloading of aircraft

- Identification of all hazardous items at the security gate

The SHELL model and 5M model are probably equally popular in the aviation industry. As you can see, they are fairly similar.

What Should an SMS Operational Risk Profile Have

An ORP should have the following elements:

- Description of each System, in which you will use your SHELL or 5M (or other) model to list all safety resources and activities needed to mitigate hazards in that System

- A “System” is a distinct segment of your operations, such as Flight Ops, Ground Ops, etc., that has distinct resources/activities

- A list of all identified hazards for each system;

- A list of all potential risks (risk occurrences) associated with each hazard;

- A risk assessment for each identified potential risk (risk occurrence);

- A list of risk controls that are associated with each hazard to successfully mitigate that hazard's potential risks

Furthermore, you should easily be able to document when each hazard, risk and control was reviewed. As new safety elements are identified in day-to-day operations, the ORP will need to be updated accordingly.

Having an ORP in this format will satisfy oversight agencies’ safety risk management process requirements, such as in the case of the FAA.

Related Aviation SMS Risk Management Articles

- Types of Operational Risk for Airline SMS

- 3 Levels of Aviation SMS Operational Excellence

- How to Prepare for Operational Safety Assurance in Aviation SMS?

What an Operational Risk Profile Looks like in Real SMS Program

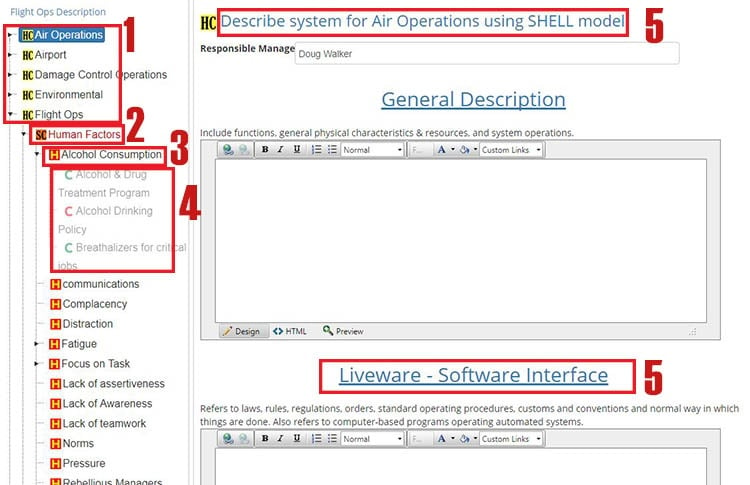

Here is an example of ORP that was built for compliance standards, and then industry-tested for usability.

You can see in the above image that in the left-hand tree:

- Each top-level item is a different “system”

- Within each system, all hazard categories are listed

- Within each hazard category, all identified hazards are listed

- All relevant risk controls are applied to the hazard

- To the right, you will use the chosen model (in the example, SHELL) to describe the System

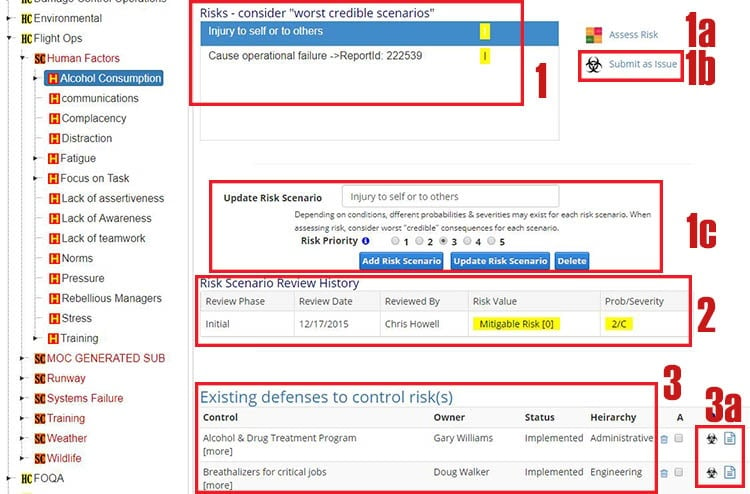

In the diagram below, you can see how this ORP addresses identifying risks and risk controls

- Each identified potential risk occurrence is listed here

- You can risk assessing each potential risk occurrence

- Or submit the potential risk as a safety issue, such as if the risk occurrence’s risk assessment is too high

- Add new risk occurrences

- View risk assessment history for the selected risk occurrence

- Review control measures that have been assigned to this selected hazard

- You can submit each control as an issue or change management if the control measure is not performing

You can generate reports for each hazard, which will format all of this information to be nice and pretty. You can also generate your entire operational risk profile report, which will show each system/hazard/risk/control in a nicely formatted document.

In such an SMS program, with auditors asking you for your ORP, you can just hand them the document.

Final Thought: Tips for Building Your ORP

Creating your ORP is a heavily top-down process. You first need to brainstorm all resources that will affect safety. This includes questions like:

- What is our existing knowledge about safety incidents, such as identifying hazards, risks, control measures, etc.?

- What is our current process for managing risk?

- What is our current strategy for proactively preventing hazard/risk occurrence?

- What bureaucratic elements are currently in place that pertain directly to safety?

- What are the good/bad elements of safety culture, and how do they affect safety?

As you can see, this process simply involves approaching your SMS program from many different angles (bureaucratically, culturally, functionally, etc.) and considering its safety elements.

For more information about ORPs and the risk management process, or to see a video demo of a top-quality ORP in action, these resources should prove valuable:

Last updated July 2025.