What Is SMS Design

SMS design is the foundation of your safety program. It is the Safety Risk Management pillar portion of the 4 Pillars of SMS.

When building your safety program, establishing a thorough, encompassing design will be the first major milestone of your SMS.

The design of your SMS is broken into five parts, following the SRM process:

- Describing your SMS and the context of your operations, such as applicable resources, locations, etc.;

- Documenting all identified hazards in your operations;

- Analyzing each hazard and understanding its root cause, mechanisms, and, most importantly, a list of associated risk occurrences;

- Ranking the risk level of each risk occurrence to understand the overall risk potential of each hazard; and

- Documenting all risk controls used to mitigate the risk.

The design of your SMS is the structure in which all SMS activities and performance will occur.

Best Practices for SMS Design

Designing your SMS program is an extensive project that will take many years. It’s also a responsibility that many safety managers struggle with because:

- There are no best practices guidelines;

- It’s easy to make mistakes; and

- It’s not always clear what needs to be done.

Fortunately, we have seen many aviation service providers implement their SMS design and see patterns in successful implementation. Here are best practices for SMS design:

- Use implementation plan checklists;

- Pick a model, such as 5Mor SHELL, to describe your SMS;

- Your organization should, depending on the size of your company, have one to multiple systems that should be described separately, such as:

- A maintenance system

- A ground ops system

- A flight ops system

- Every time something new is added to your operations, your SMS design documentation should be updated – “something new” can be:

- A policy

- A procedure

- A new hazard

- A new risk control

- When confused, reach out and seek guidance from veteran safety managers.

Implementation plan checklists will help ensure that your SMS design is implemented without missing important aspects of the SMS. Continuous design updating ensures that your SMS design will always be up to date.

Related SMS Design and Performance Articles

- Best Practices for Designing Your SMS for Aviation Service Providers

- How to Measure Safety Performance in Aviation SMS

- 4 Ways to Significantly Improve Safety Performance Using Aviation SMS

What Is SMS Performance

SMS performance is the conglomeration of outcomes of safety mitigation that the SMS design describes. Safety outcomes can be measured by the initial risk assessments of reported safety issues. More specifically, you will measure safety performance in your SMS with:

- Key performance indicators (KPIs);

- Aviation leading indicators; and

- Data charts and other metrics.

In terms of performance, your priority is that your KPIs are being reached, as they represent whether or not your safety goals and objectives are being fulfilled.

Outcomes of reaching your safety objectives and other mitigation efforts should be largely influenced by the design of your SMS. When aviation SMS designs are “fully implemented” but the performance of the SMS is poor, it indicates a faulty design.

SMS design and performance should be fairly in sync. A fully designed and implemented SMS should result in at least a moderate safety culture and moderate performance. It’s not uncommon for performance and culture to lag behind SMS design for some time.

However, once the design is fully complete and implemented, you should see a steady increase in safety performance.

Best Practices for SMS Performance

Best practices for safety performance depend on several factors:

- The size of your organization;

- The current level of performance of your SMS;

- How old your SMS is;

- How implemented the design of your SMS is;

- Existing safety culture; and

- Quality of existing resources (i.e., spreadsheets vs integrated SMS database).

Some general best practices are:

- Make sure you have quality key performance indicators;

- Use aviation leading indicators where applicable;

- Understand how critical Safety Promotion is for driving safety performance; and

- Work constantly to understand and improve your safety culture.

How SMS Design and Performance Interact

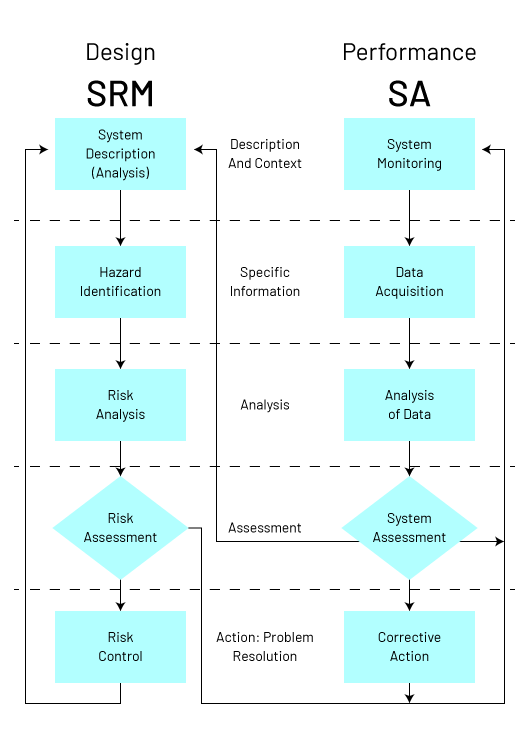

The interaction of design and performance is summarized in the graphic to the right. This is an important structure, as it guides the design vs performance problem.

Here’s what this graphic describes:

- During operations, your Safety Assurance process monitors the operational environment performance;

- When submitted issues are assessed (System Assessment) to see whether the SMS successfully mitigates the reported concern, there are two outcomes:

- SMS remains within an ALoS given the reported issue

- SMS escalates to an unacceptable level of safety given the reported issue

- When an SMS is given a scenario where it is not within an acceptable level of safety, the design of the SMS needs to be updated; and

- This sets off the design process (i.e., the SRM process), where the new scenario is processed as described in the first section.

What Is Performance Lock

Performance lock is an extremely important concept to understand when discussing the design vs performance problem. Performance lock is when SMS performance plateaus, and cannot improve.

Why does this happen?

- SMS only puts our fires from reported issues, audit findings, etc.;

- No urgency to ensure updating the design;

- Not enough resources for safety manager/team to implement design or update design;

- Inadequate SMS education;

- Lack of effective oversight; and

- Lack of proper use of SMS resources.

For all reasons, the result is poor design update. As SMS performance will always lag behind the SMS design, if the SMS design is not continuously updated then the SMS performance cannot continuously improve.

What is the quality of your SMS and SMS design? Take this free quiz to find out:

Last updated February 2025.